About Our Company

China Brake shoe factory and supplier

Santa Brake’s brake pad and brake shoe factory was established in 2010. In addition to the production of automotive brake pads, we also have a professional production line for automotive brake shoes. Our factory can supply more than 1 million sets of brake shoes per year, which are suitable for passenger cars, commercial vehicles and various trucks. Our brake shoes are exported to many countries and regions such as Europe, America, Japan and Korea, Middle East, South America and Africa.

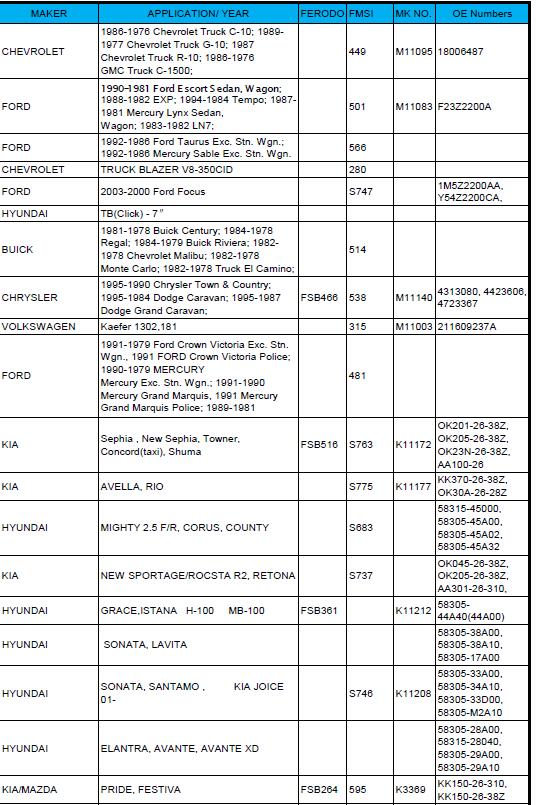

Our brake shoes products cover more than 800 models, which can cover 90% of the mainstream vehicles in the market at present. Our brake shoes are mainly available in semi-metal and ceramic formulations, and we are able to provide customized products according to different customer needs. In addition, we have a strict quality control system and cost control system, which enables us to provide you with more competitive and higher quality brake shoes.

Please contact us to learn more about our products!

Brake Shoe Manufacturing Process

The first step in the production process is the stamping of the brake shoe plate. Steel sheets of different thicknesses are stamped into brake shoe components piece.

The second step is to weld the stamped shoe assembly on a professional welding machine to form a complete shoe. The curvature of the shoes is also checked at the same time.

According to different formula, the mixed friction materials are pressed on the press machine under the set temperature and pressure to form the brake shoe friction material linings.

The friction material lining is evenly coated with glue. The quality of the glue application will affect the tightness of the bond between the friction material and the brake shoes plates.

The friction lining and brake shoes plate are snapped together and placed in a professional grinding tool to press them together. Then put them into the bonding line.

The curvature and size of the finished brake shoes are carefully inspected. Then the qualified products are packed into the branded boxes specified by the customer.

We Can Supply All Kinds of Brake Shoes (3)

Key Reasons of Choosing Santa Brake

As a Brake Shoes Supplier (3)

Our Advantage as a Qualified

Brake Shoes Manufacturer

We have more than 15 years of experience in the production of brake shoes

Strictly follow TS16949 production system for production process arrangement and quality control

Strict requirements on material, size and appearance of products according to OEM standards

Approved by more than 50 customers in more than 20 countries and regions around the world

We have a professional production and sales service team

Never-ending pursuit of improving product quality and reducing costs

- Certification

- Quality Control

- Catalogue

- Videos

- All You Need to Know About Brake Shoes

Our brake shoe factory has a series of quality management system certifications and product quality test reports. For example, TS16949 production management system certification, AMECA product certification, Link product test reports, R90 Emark product certification, etc.

If you’re driving a car, you’ve likely heard of brake shoes. But what are they and how do they work? There are several types of brake shoes, and each one has its own benefits. Here are a few things to know about brake shoes, from their material to how they work.

What is a brake shoe?

The brake shoe is a part of your car’s braking system that works to control the amount of friction in the braking system. Its material is made to withstand high levels of friction and is designed to wear well. It is also easy to notice when a shoe starts to wear since you will notice weaker stops and your pedal will need more contact.

The shoe is made from a variety of materials, and it works with drum brakes and disc brakes. It is used in the automotive, railway, cycling, and agricultural industries. There are several types of brake shoes, each made for a particular application. In the past, brake shoes were often made of asbestos, but that material has been phased out due to its adverse health effects. Today, synthetic aramid and other materials are used in brake shoes. However, the cost of replacement may be higher for brake shoes made of synthetic fibers.

Brake shoes are curved metal pieces that have friction material on one side. This material is called the brake lining and is composed of various materials that provide perfect traction on the brake drum. The brake shoes themselves contain many other components, which make them an important part of your braking system.

How do brake shoes work?

Brake shoes are a vital part of your vehicle’s braking system. They can wear out over time, so it’s important to replace them as needed. To replace them, remove the old one by unscrewing the adjusting screw with a wrench. Then, insert the new one, facing the appropriate way. It should touch the drum but not rub against it.

The friction between the brake shoes and the wheel slows the wheel proportionally to the force applied to it. Disc brakes, on the other hand, use a disc brake that does not make direct contact with the wheel. This friction generates a large amount of heat. However, the shoes still need to hit their mark because of thermal expansion.

The brake shoe has two components, the brake block, and the brake lining. The block is originally made of wood, but later on, it was made of cast iron or grey iron. When the shoe presses against the wheel tread, it scrubs it. This causes the tread to wear and causes the brake to squeal. Nowadays, passenger trains use disc brakes instead of tread brakes.

Brake shoes are a vital part of braking systems. They apply friction to the wheel to slow wheels. When the driver presses the brake lever, the brake fluid begins to travel to individual braking mechanisms and amplifies the force. The hydraulic fluid then engages a small hydraulic pump in a brake shoe that stretches the brake pad, which then applies force to the spinning wheel.

Types of brake shoes

There are many different types of brake shoes, and identifying the right type for your vehicle can help you stop your vehicle safely. Brake shoes are designed to work with the drum to create friction that slows the wheels of your vehicle down when you apply the brakes. Over time, brake shoes can begin to wear out and should be replaced when necessary to provide better braking power.

While most vehicles are equipped with a warning light to indicate that brake shoes need to be replaced, there are also other signs to check for. For example, if you notice that the base of the brake shoes is grinding and has bright iron filings near the rim, you should replace your shoes. Even if you don’t see any signs of wear, you should listen to the “iron friction iron” sound when you apply the brakes. If you hear this sound, you should replace your brake shoes immediately.

Some vehicles require brake shoes that are more durable than others. Brake shoes come with either primary or secondary shoes. The secondary shoe is typically larger and relies on its bigger surface area to absorb the braking force. The primary shoe is supported by an array of springs and is attached to a steel support plate.

Material of brake shoes

They are available in many different materials and are designed according to various specifications and applications. In the past, asbestos was used in nearly every brake system but the hazards associated with asbestos led to the development of alternative materials. Today, brake shoes are made of steel, iron, copper, or alloys.

Generally, brake shoes are made from a high-friction material like steel or aluminum. In some cases, the friction material is made of a composite material. Woven kevlar, for example, has high friction properties at high and low temperatures. It can also be bonded to steel or aluminum brake shoe cores. This type of material is widely used in vintage racing and touring events and is trusted by mechanics who want to make sure that their brakes are as safe as possible.

The primary function of brakes is to slow a car down. When you slow a car by applying pressure on the brakes, the car converts kinetic energy into heat. This friction generates enormous amounts of heat in the brake shoes. This heat can damage the shoes and affect their performance.

How to choose a brake shoes supplier?

If you’re looking to replace your brake shoes, there are several things you should consider. Relining your existing brake shoes may save you money upfront, but new ones will last longer and add more protection to your drums and linings. Buying new ones can also save you money over time on core handling costs, such as fuel and vehicle wear.

When choosing brake shoes, make sure to consider the manufacturer’s quality control. Brake shoes are often manufactured in different types of alloys and can be made with different types of material. While steel and iron are the most common materials for brake shoes, copper and other materials are also acceptable. Just make sure that the alloys you choose have adequate heat resistance.

Brake shoes are relatively inexpensive, but you should make sure you choose a premium manufacturer. Choose a company with excellent customer service and a proven track record. Choose a manufacturer that uses the highest quality materials and combines them with other quality materials. This can increase product life by as much as 30%

FAQ

50-100 sets for each model MOQ, 1000 sets for each order MOQ.

Yes, if your total order exceeds 2000 sets, we can pack the brake shoes in branded color boxes according to your requirements.

30% in advance, 70% before delivery.

The warranty is 40,000km or 18 months.

You can organize the OEM number of the product you need or the product number of other famous brands, we can make inquiries and quotations.